Empty Dunk Tank, Broken Barrier?

The hidden risks of standard dunk tanks and drained systems

Some dunk tanks only maintain their seal when liquid is present. That means when the tank is drained for cleaning, servicing or shutdown, your containment barrier could be compromised.

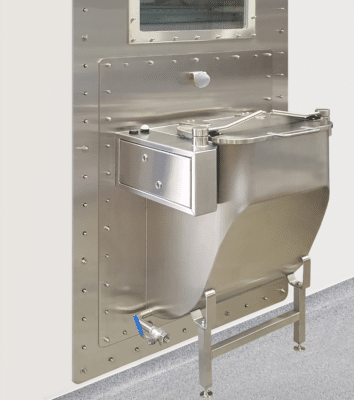

As a manufacturer of decontamination equipment for BSL-3 and BSL-4 environments, we designed our HC-DT Dunk Tank to maintain integrity at all times.

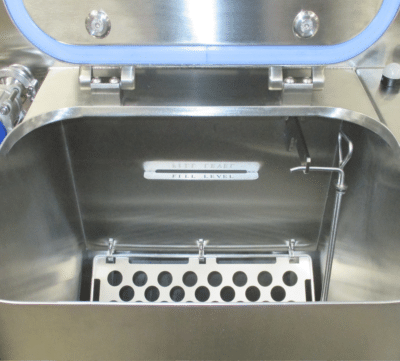

- Airtight stainless steel lids that provide a seal even when the tank is empty

- Optional live liquid transfer to allow changeover without breaking containment

- Cast stainless steel hinges to ensure repeatable, long-term performance

- Manual locking mechanism for secure shutdown

- PLC control options for immersion timing and integration with access systems

Why tank integrity matters: preventing leakage, non-compliance and human error

- Prevents hidden leakage paths during downtime

- Keeps your facility compliant 24 hours a day, not just during operation

- Reduces the risk of operator error or reliance on procedural workarounds

Containment must remain intact even when a tank is empty. At PBSC we design for real-world scenarios because every transfer point is a potential weak point. If you would like to discuss how the HC-DT Dunk Tank can be tailored to your facility, let us know.

- Previous

- Next