Ensuring Visibility Without Compromising Containment

Why vision panels matter: balancing operator sightlines with containment performance

In high-containment and cleanroom environments, vision panels are often treated as secondary to doors, walls or air systems. They can, however, be a critical weak point. Here is what to consider when designing vision panels that keep operators safe and facilities compliant while still providing essential visibility.

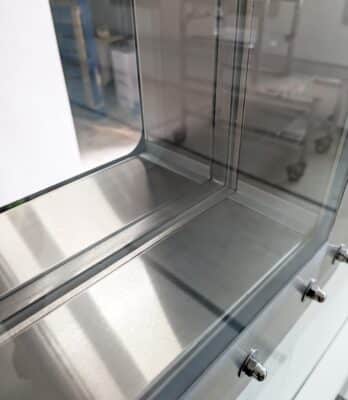

Flush glazing for cleanability: reducing ledges and contamination havens

Flush-fitted panels reduce ledges and joins where contaminants can collect.

- Double-glazed options ensure a smooth finish on both sides of the wall.

- Easy to clean, visually seamless and compliant with sterility requirements.

Pressure integrity & redundancy: glazing engineered for differential pressures

High-containment glazing can resist differential pressures up to 2000 Pa without leakage.

- Double glazing solutions provide added redundancy by design.

- Cast concrete installations with built-in test points allow fast, reliable pressure checks during validation.

Frames that match facility demands: sealed, durable interfaces for any wall type

Stainless steel frames are mechanically sealed with compression gaskets.

They are compatible with concrete, blockwork or stud partition wall types.

Testing & maintenance built-in – cast concrete wall installations for repeatable checks

Regular integrity testing should be straightforward.

- Integrated pressure points make leakage checks quick and repeatable.

- Panels designed for easy access and long-term durability simplify servicing.

Tailored options for special requirements: fire, security, acoustic and radiation needs

Options include:

- Fire-rated versions up to 120 minutes for added safety.

- Security glazing tested to SR5 standard for high-risk facilities.

- Acoustic upgrades to improve operator comfort.

- Internal blinds or roller shades to control visibility when required.

- Lead shielding up to 12 mm equivalence.

Why it matters: combining clear visibility with uncompromised containment

Vision panels should not compromise your barrier. The right design combines:

- Clear operator visibility

- Full containment performance

- Flexibility to meet fire, security or acoustic needs

That is why PBSC’s engineered solutions are trusted in BSL2 to BSL4 facilities worldwide, ensuring operators can see clearly without compromising safety. If you are planning or upgrading a containment facility, let us discuss how vision panels can be tailored to your needs.